INDUSTRIAL VISIT TO KARE PROSTHETICS AND ORTHOTICS

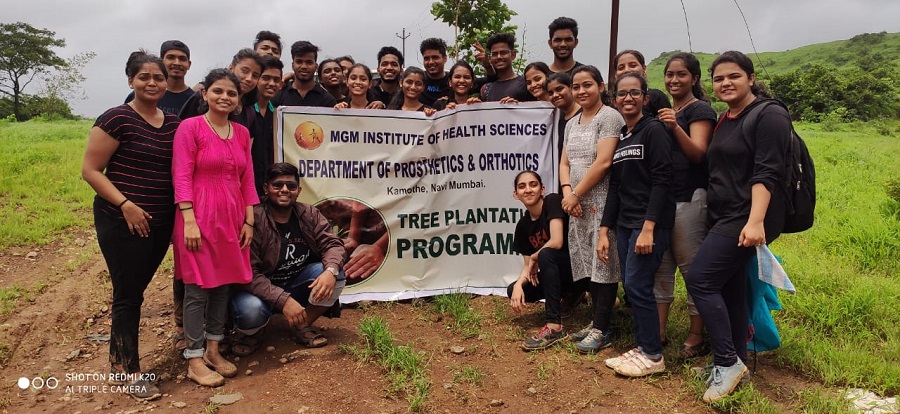

On February 12, 2024, 21 students from MGMIUDPO embarked on an educational journey to a Kare Prosthetic and Orthotic Center, Bangalore aiming to gain insights into the world of prosthetics and orthotics accompanied by the Head of the Department Dr. Uttara Deshmukh (P&O). The experience proved to be enlightening and transformative, offering a deeper understanding of the field and its impact on individuals' lives. Upon arrival, the students were greeted by a team of professionals dedicated to improving the quality of life for individuals with limb loss or orthopedic impairments. The tour commenced with an overview of the center's mission, highlighting its commitment to innovation, compassion, and patient-centric care.

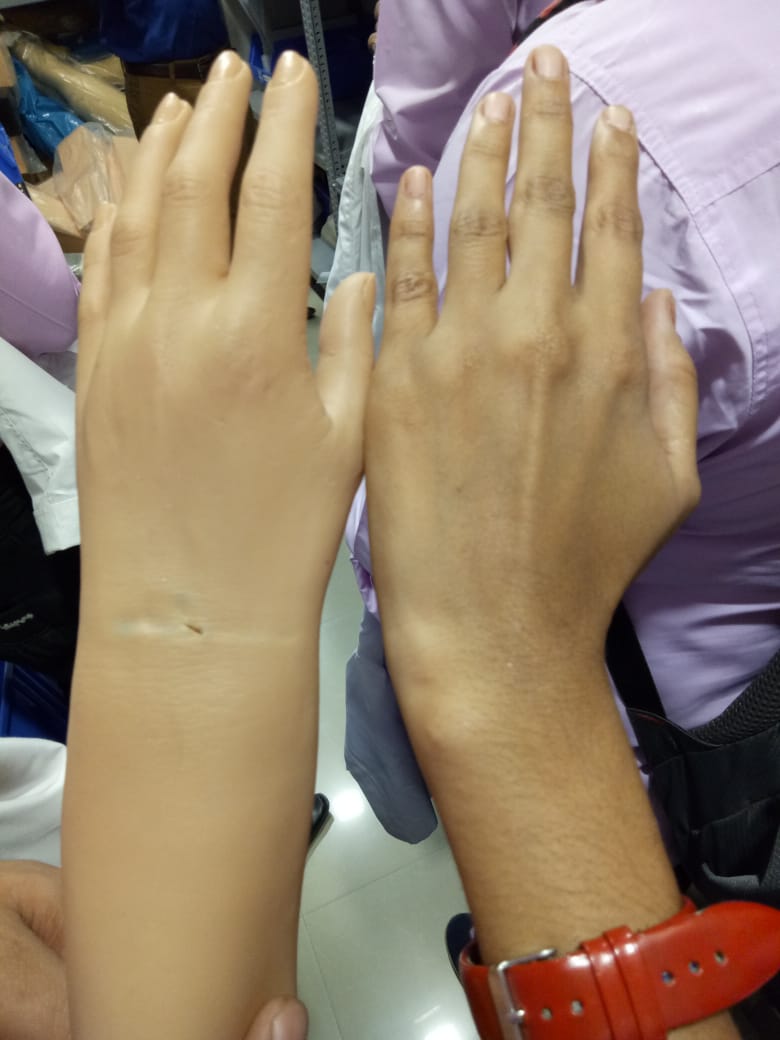

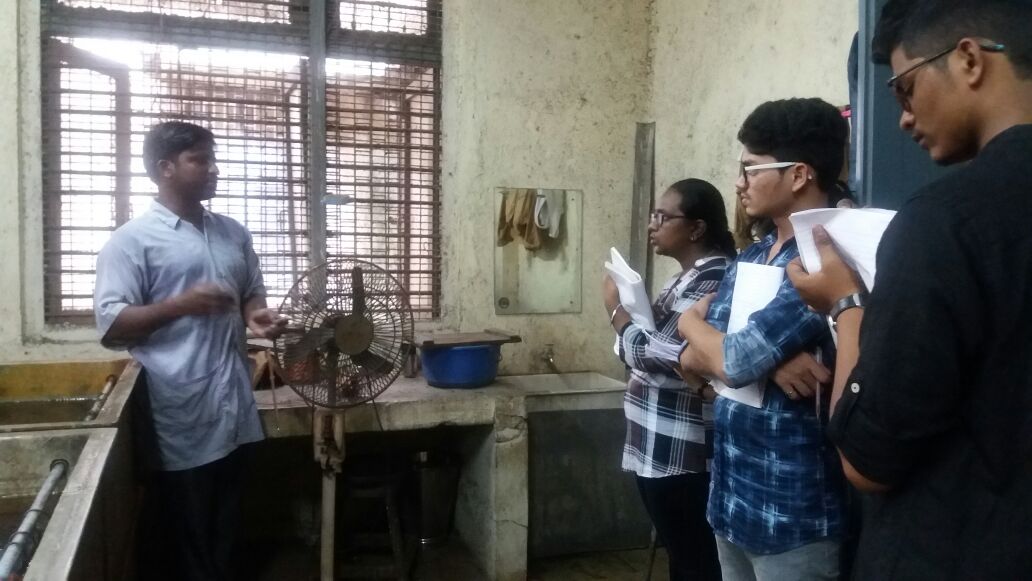

The students were then guided by a Orthotist being employed there Mr. Neville Joshi. He guided us from initial assessments and measurements to the fabrication and fitting process, each step was explained in detail, emphasizing the importance of precision and customization to meet the unique needs of every patient.

One of the most impactful moments of the visit was witnessing a fitting session, where a patient who was just 4 months old received their newly crafted Cranial Helmet. These type of fitting and fabrication aren’t generally seen in a day to day life.

In addition to the technical aspects, the students also gained insights into the psychosocial dimensions of prosthetic and orthotic care. They learned about the importance of empathy, communication, and ongoing support in helping patients navigate the physical and emotional challenges of rehabilitation.

Mr. Neville walked the students through his clinic which had separate counselling rooms, modification rooms, assessment rooms, and a large fabrication area for fabricating prostheses & orthoses.

As the visit came to close, the students le ft with a newfound appreciation for the field of prosthetics and orthotics, inspired by the resilience of both patients and practitioners alike. The experience served as a reminder of the power of innovation and compassion in transforming lives and reaffirmed their commitment to making a difference in the lives of others.

No. of participants visited: 1 Faculty & 21 Students of MGMIUDPO.

Date - :12th February 2024